By Sarah Yang, Media Relations | October 14, 2014

BERKELEY — UC Berkeley scientists have taken proteins from nerve cells and used them to create a “smart” material that is extremely sensitive to its environment. This marriage of materials science and biology could give birth to a flexible, sensitive coating that is easy and cheap to manufacture in large quantities.

The work, published today (Tuesday, Oct. 14) in the journal Nature Communications, could lead to new types of biological sensors, flow valves and controlled drug release systems, the researchers said. Biomedical applications include microfluidic devices that can handle and process very small volumes of liquid, such as samples of saliva or blood, for diagnostics.

“This work represents a unique convergence of the fields of biomimetic materials, biomolecular engineering and synthetic biology,” said principal investigator Dr. Sanjay Kumar, UC Berkeley professor of bioengineering. “We created a new class of smart, protein-based materials whose structural principles are inspired by networks found in living cells.”

Kumar’s research team set out to create a biological version of a synthetic coating used in everyday liquid products, such as paint and liquid cosmetics, to keep small particles from clumping together. The synthetic coatings are often called polymer brushes because of their bristle-like appearance when attached to the particle surface.

To create the biological equivalent of a polymer brush, the researchers turned to neurofilaments, pipe cleaner-shaped proteins found in nerve cells. By acting as tiny, cylindrical polymer brushes, neurofilaments collectively assemble into a structural network that helps keep one end of the nerve cell propped open so that it can conduct electrical signals.

“We co-opted this protein and turned it into a polymer brush by cloning a portion of a gene that encodes one of the neurofilament bristles, re-engineering it such that we could attach the resulting protein to surfaces in a precise and oriented way, and then expressing the gene in bacteria to produce the protein in large, pure quantities,” said Kumar. “We showed that our ‘protein brush’ had all the key properties of synthetic brushes, plus a number of advantages.”

Kumar noted that neurofilaments are good candidates for protein brushes because they are intrinsically disordered proteins, so named because they don’t have a fixed 3-D shape. The size and chemical sequence of these hair-like proteins are far easier to control when compared with their synthetic counterparts.

“In biology, precision is critical,” said Kumar. “Proteins are generally synthesized with the exact same sequence every time; the length and biochemical order of the protein sequence affects all of its properties, including structure and the ability to bind to other molecules and catalyze biochemical reactions. This kind of sequence precision is difficult if not impossible to achieve in the laboratory using the tools of chemical synthesis. By harnessing the precision of biology and letting the bacterial cell do all the work for us, we were able to control the exact length and sequence of the bristles of our protein brush.”

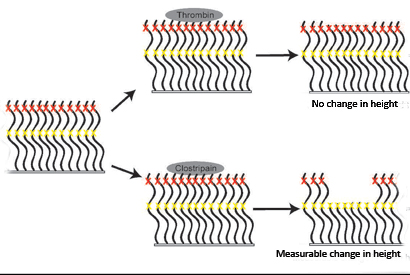

The researchers showed that the protein brushes could be grafted onto surfaces, and that they dramatically expand and collapse in reaction to changes in acidity and salinity. Materials that are environmentally sensitive in this way are often referred to as “smart” materials because of their ability to adaptively respond to specific stimuli.

Other co-authors on the paper are Nithya Srinivasan, Maniraj Bhagawati, and Badriprasad Ananthanarayanan, all of whom are postdoctoral fellows in Kumar’s lab.

This work was supported by a Presidential Early Career Award for Scientists and Engineers from the Army Research Office and a Hellman Faculty Fund Award, both given to Kumar.